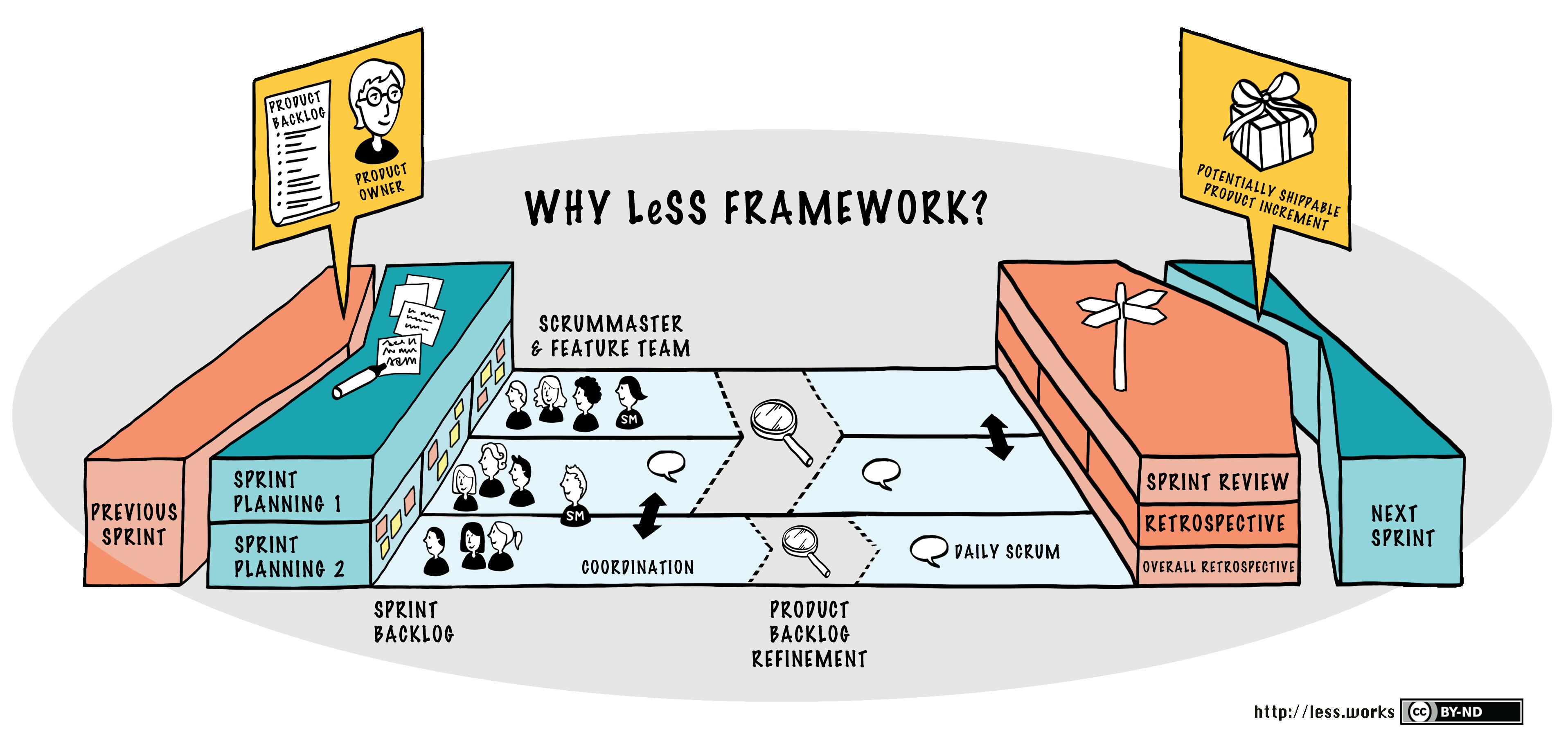

LeSS (Large-Scale Scrum Framework) is more than a set of principles and experiments. It also provides a framework with rules. The LeSS Rules define what is LeSS (and what isn’t) and they provide a concrete framework for applying LeSS. Within the LeSS Framework, product groups can apply the experiments and discover what works best for them at a certain moment.

According to LeSS:

“There are no such things as best practices. There are only practices that are good within a certain context.”

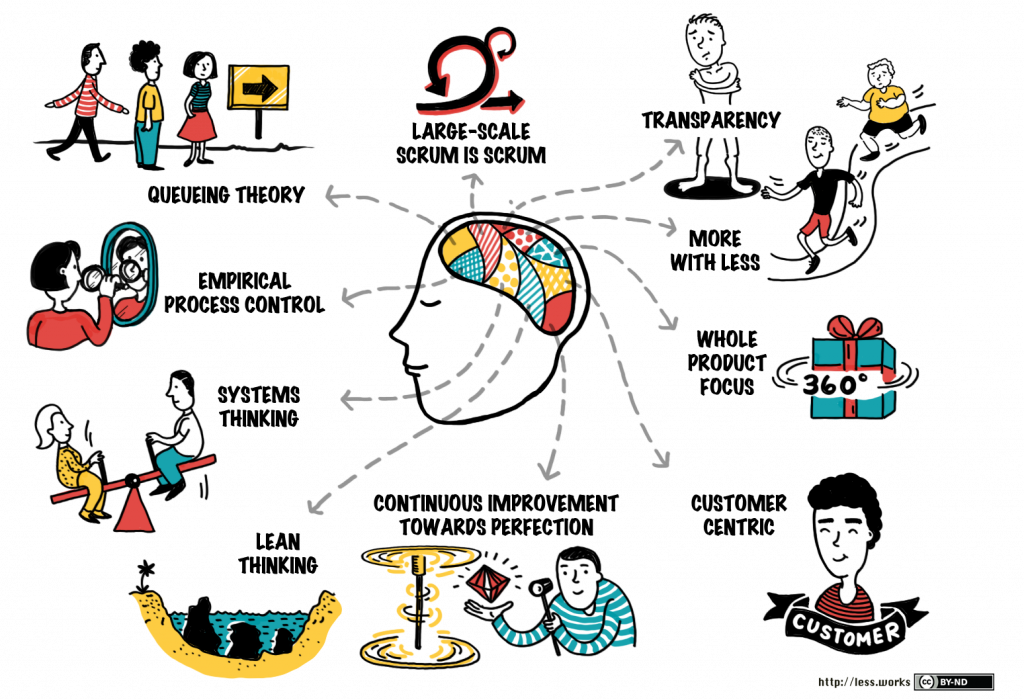

10 LeSS Principles

The 10 LeSS Principles:

- Large-Scale Scrum is Scrum

- Empirical process control

- Transparency

- More with LeSS

- Whole-product focus

- Customer-centric

- Continuous improvement towards perfection

- Systems thinking

- Lean thinking

- Queuing theory

Large-Scale Scrum is Scrum

What “Is” LeSS?

“LeSS is about applying the principles, elements, and purpose of Scrum in a largescale context for multiple-team Scrum, not multiple Scrum teams.”

What “Is Not” LeSS?

LeSS is not “new and improved Scrum.”

Empirical process control

Inspection and adaptation of the product, processes, organizational design, and practices to craft a situational appropriate organization based on Scrum, rather than following a detailed formula. And empirical process control requires and creates transparency.

Transparency

Based on tangible ‘done’ items, short cycles, working together, common definitions, and driving out fear in the workplace.

More with LeSS

- In empirical process control: more learning with less defined processes.

- In lean thinking: more value with less waste and overhead.

- In scaling, more ownership, purpose, and joy with fewer roles, artifacts, and special groups.

Whole-product focus

One Product Backlog, one Product Owner, one potentially shippable product increment, one Sprint—regardless if there are 3 or 33 teams. Customers want the product, not a part of it.

Customer-centric

Identify value and waste in the eyes of the paying customer. Reduce the cycle time from their perspective. Increase feedback loops with real customers. Everyone understands how their work today directly relates to paying customers.

Continuous improvement towards perfection

Create and deliver a product all the time, without defects, that utterly delights customers, improves the environment, and makes lives better. Do humble and radical improvement experiments each Sprint towards that.

Systems thinking

See, understand, and optimize the whole system (not parts), and explore system dynamics. Avoid the local and sub-optimizations of focusing on the ‘efficiency’ or ‘productivity’ of individuals and individual teams. Customers care about the overall concept-to-cash cycle time and flow, not individual steps.

Lean thinking

Create an organizational system whose foundation is managers-as-teachers who apply and teach systems thinking and lean thinking, manage to improve, and who practice Go See at gemba. Add the two pillars of respect for people and continuous improvement. All towards the goal of perfection.

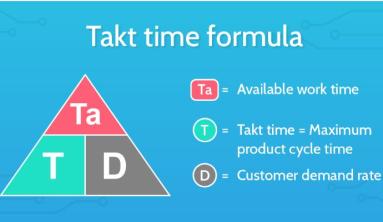

Queuing theory

Understand how systems with queues behave in the R&D domain and apply those insights to managing queue sizes, work-in-progress limits, multitasking, work packages, and variability.